6 steps for diversifying supplier base: Enhance your supply chain

Table of Content

- Introduction

- 6 Secrets to Supplier Base Diversification: How to diversify supplier base?

- 1. Evaluate Current Suppliers

- 2. Research Potential Suppliers

- 3. Establish Criteria for Selection

- 4. Build Relationships with New Suppliers

- 5. Pilot Test New Suppliers

- 6. Maintain and Review Supplier Relationships

- Models of supplier engagement

- What implementation challenges do an importer face while diversifying supplier?

- Case study

- Pitfalls to Avoid: Mitigate the risk of failure while diversifying supplier:

- Conclusion

Introduction

In an era where supply chain disruptions can significantly impact business operations, diversifying your supplier base has never been more critical. Relying on a single or limited number of suppliers exposes your business to various risks, from geopolitical tensions to natural disasters. By strategically expanding and diversifying your supplier network, you not only mitigate these risks but also enhance your business’s resilience and flexibility. This guide reveals five essential secrets to effectively diversify your supplier base, ensuring that your business remains robust, competitive, and prepared for any challenges that arise.

Social Media Handles

6 Secrets to Supplier Base Diversification: How to diversify supplier base?

1. Evaluate Current Supplier

a) Assess existing supplier’s performance:

Before expanding your supplier network, take a critical look at your current suppliers. Evaluate their performance meticulously. Are they meeting delivery schedules consistently? Is the quality of their products up to your standards? Are they proactive in addressing issues? A thorough performance audit reveals who truly adds value to your business and who falls short.

b) Identify Potential Risks and Weaknesses:

Every supplier has potential risks and weaknesses, whether it’s financial instability, geopolitical risks, or a lack of innovation. Identifying these vulnerabilities early helps in making informed decisions. Evaluate factors such as dependency on a single supplier, exposure to currency fluctuations, and the impact of local regulations. By understanding these risks, you can better prepare for unforeseen disruptions.

2. Research Potential Suppliers

a) Conduct Market Research:

Market research is the cornerstone of finding new suppliers. Dive deep into industry reports, case studies, and white papers. Analyze market trends and emerging suppliers who are gaining traction. This comprehensive understanding of the market landscape aids in identifying suppliers who align with your business goals.

b) Utilize Online Platforms and Directories:

Online platforms like Alibaba, Global Sources, and ThomasNet offer a treasure trove of potential suppliers. These directories allow you to filter suppliers based on criteria such as industry, location, and certifications. Engage with these platforms to discover suppliers who may not be on your radar yet.

c) Attend Trade Shows and Exhibitions:

Trade shows and exhibitions are invaluable for networking and discovering new suppliers. These events provide a firsthand look at products and innovations, enabling direct interactions with potential suppliers.

d) Partner with Local sourcing companies/buying agents

Network with industry professionals and seek recommendations to expand your list of potential vendors. Don’t overlook the importance of engaging with local chambers of commerce and local buying agents /sourcing companies, as they can provide valuable resources, connections, and insights into the respective country market.

3. Establish Criteria for Selection

a) Define Criteria Based on Business Needs:

Defining clear criteria based on your business needs is crucial. Determine what’s essential for your operations—is it cost efficiency, superior quality, or swift delivery times? Tailor your criteria to reflect your strategic priorities, ensuring alignment with your overarching business objectives.

b) Consider Factors Such as Reliability, Quality, and Cost:

While defining criteria, consider factors such as reliability, quality, and cost. A reliable supplier consistently meets deadlines and handles issues proactively. Quality should never be compromised; seek suppliers with robust quality control measures. Costshould be weighed against the value provided. Balancing these factors ensures a holistic selection process.

4. Build Relationships with New Suppliers

a) Initiate Contact and Express Interest:

Initiate contact with potential suppliers by expressing genuine interest in their offerings. A personalized approach, highlighting specific aspects of their products that appeal to you, sets a positive tone. Clear, respectful communication fosters goodwill and opens doors for further discussions.

b) Communicate Expectations and Requirements:

Transparency is key. Clearly communicate your expectations and requirements from the outset. Detail your quality standards, delivery timelines, and any specific needs. This clarity helps in aligning both parties and setting the stage for a successful partnership.

b) Visit Supplier Facilities if Possible:

If feasible, visiting supplier facilities provides invaluable insights. A firsthand look at their operations, quality control processes, and working conditions helps assess their capability to meet your demands. It also strengthens the relationship, showing your commitment to a potential partnership.To save on your time and money you can associate with the sourcing companies or buying agents to do this job on your behalf. It has been proven that if you have someone local who acts as your eyes and ears in respective country it adds the significant value to your sourcing journey giving you the assured quality products at much affordable rates ensuring the supplier you chose to work with is genuine and trustworthy.

5. Pilot Test New Suppliers

a) Start with Small Orders:

Begin with small orders to test new suppliers. This approach minimizes risks while allowing you to evaluate their performance. It’s a practical way to gauge their reliability, quality, and responsiveness without significant financial exposure.

b) Monitor Performance and Quality:

Diligently monitor the performance and quality of your initial orders. Track key metrics such as delivery timeliness, defect rates, and communication effectiveness. This data-driven approach helps in making informed decisions about scaling up orders.

c) Provide Feedback and Address Issues Promptly:

Feedback is crucial for continuous improvement. Provide constructive feedback to new suppliers and address any issues promptly. Open communication ensures that any concerns are rectified swiftly, fostering a collaborative and adaptive partnership.

6. Maintain and Review Supplier Relationships

a) Regularly Assess Supplier Performance:

Regular assessment of supplier performance is essential. Partner with a sourcing agency like Azoonis, that specializes in helping importers evaluate supplier performance through continuous inspections and frequent visits. This hands-on approach ensures you receive detailed, up-to-date insights into your suppliers’ operations, allowing you to stay informed and proactive.

b) Communicate Openly and Transparently:

Maintain open and transparent communication with your suppliers. Regular updates, honest feedback, and clear expectations build trust and strengthen relationships. This transparency ensures alignment and mutual understanding, crucial for long-term collaboration.

c) Continuously Seek Improvement Opportunities:

Never settle for the status quo. Continuously seek improvement opportunities within your supplier relationships. Whether it’s through process optimizations, cost-saving innovations, or quality enhancements, an ongoing commitment to improvement ensures your supply chain remains robust and competitive.

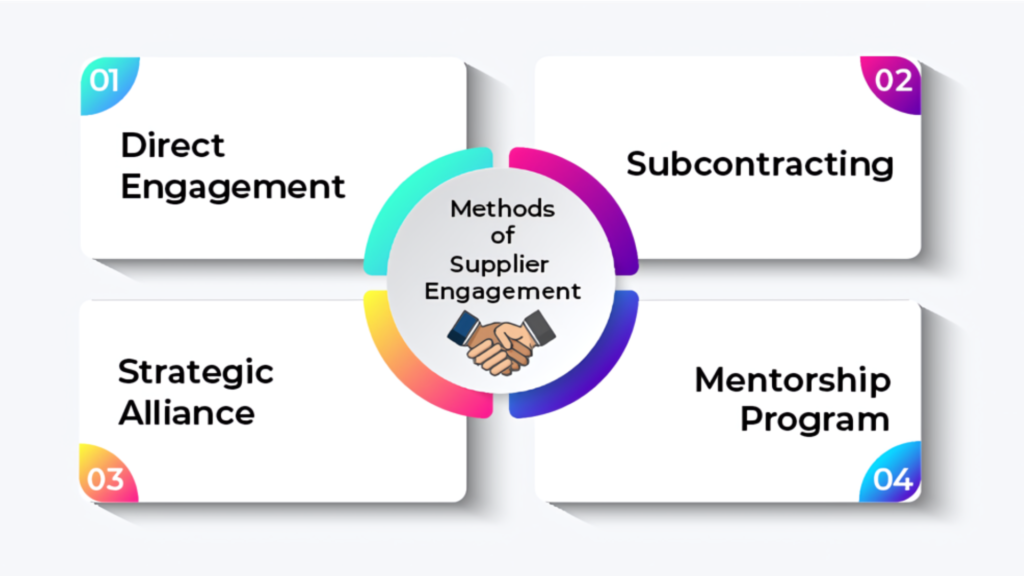

Models of supplier engagement

1. Direct Engagement

In the direct engagement model, the client establishes a direct relationship with a certified diverse supplier. This approach allows the firm to have full visibility and control over the supplier’s operations, making it easier to monitor performance and ensure compliance with the company’s standards and expectations. By working closely with the diverse supplier, the client can foster a strong partnership, directly influence the supplier’s processes, and swiftly address any issues that may arise. This direct line of communication enhances transparency and accountability, leading to more effective and efficient collaboration.

2. Subcontracting

In the subcontracting model, the client partners with a primary supplier who then subcontracts a portion of the work to a certified diverse supplier. This setup is beneficial for clients who prefer to work through an intermediary but still wish to support diverse suppliers. The primary supplier includes the details of the diverse suppliers in the master contract, ensuring that the client is aware of their involvement. This model allows clients to leverage the expertise of their primary suppliers while also contributing to the development of diverse businesses. It also creates an opportunity for the diverse suppliers to gain experience and exposure by working under the umbrella of a more established company.

3. Strategic Alliance

The strategic alliance model involves two or more certified diverse suppliers forming a partnership to provide services to a client under a single contract. This collaborative approach allows the suppliers to combine their strengths and resources to meet the client’s needs more effectively. By working together, the diverse suppliers can offer a broader range of services, enhance their capabilities, and compete for larger contracts that they might not be able to handle individually. For the client, this model offers the benefits of dealing with a single entity while still supporting multiple diverse businesses. It also encourages innovation and synergy as the allied suppliers bring different perspectives and expertise to the table.

4. Mentorship Program

In the mentorship program model, a client engages with diverse suppliers who are being mentored by an established supplier. The established supplier provides training, guidance, and support to the diverse suppliers, helping them to improve their services and build their capacity. This model not only helps the diverse suppliers to grow and develop their skills but also ensures that the client receives high-quality services. By participating in such mentorship programs, the client can play a pivotal role in nurturing and empowering diverse businesses. This approach demonstrates a commitment to corporate social responsibility and helps to build a more inclusive supply chain ecosystem.

What implementation challenges do an importer face while diversifying supplier?

1. Initial Investment:

Starting to diversify suppliers requires a significant initial investment. This financial commitment can be overwhelming. Importers need to allocate funds for market research, vetting potential suppliers, and setting up new logistics. Upfront costs include travel for on-site visits, fees for inspections, and investments in technology to streamline communications. This phase is essential for building a solid foundation for future business operations, ensuring quality and long-term stability.

2. Coordination Efforts

a) Managing Multiple Suppliers:

After the initial investment, managing multiple suppliers becomes a challenge. This involves coordinating logistics, overcoming communication barriers, and maintaining quality control. Each supplier has different protocols and timelines, synchronization is difficult. Importers need effective systems to monitor supplier performance, including standardized procedures for order placement, delivery tracking, and inventory management. Communication can also be challenging due to language differences and time zones. Technology, such as supply chain management software, can help by providing real-time updates and facilitating smooth communication.

Case study:

Journey from 1 product category to 100+

One client, a home decor importer, had stopped sourcing from India due to poor quality and negative supplier experiences. Recognizing the market’s potential, they engaged Azoonis for a professional approach. Starting with a small order, Azoonis identified reliable suppliers through rigorous audits and ensured quality with comprehensive inspections. The client received their goods as per their expectation with zero error in production of the products, restoring their confidence in Indian suppliers and significantly increasing their orders. Azoonis’ commitment to fair pricing, top-notch quality, and timely delivery made the sourcing process seamless, establishing them as reliable partners in the client’s procurement journey. Read full case study.

Pitfalls to Avoid: Mitigate the risk of failure while diversifying supplier:

Inadequate Due Diligence

A critical mistake is inadequate due diligence. Skipping thorough research and vetting can lead to partnerships with unreliable suppliers, risking the entire supply chain. Comprehensive background checks, including financial stability assessments and reputation evaluations, are essential.

Ambiguous Contractual Agreements

Another pitfall is neglecting clear contractual agreements. Vague terms can lead to misunderstandings and disputes, which are costly and time-consuming. Importers should ensure contracts cover delivery schedules, payment terms, and quality standards.

Poor Communication Infrastructure

Failing to invest in strong communication infrastructure can hinder a diversified supplier network. Effective communication is key. Using advanced tools and fostering transparency and collaboration can significantly reduce risks.

Ignoring Cultural Differences

Importers must navigate cultural differences and varying business practices. Understanding and respecting cultural nuances fosters stronger, cooperative relationships and aids in successfully integrating new suppliers.

Conclusion

Diversifying your supplier base is not merely a strategic advantage but a necessity in today’s volatile market. By evaluating current suppliers, researching potential new ones, establishing clear selection criteria, building strong relationships, and rigorously testing new suppliers, you can create a resilient and adaptive supply chain. Leveraging the expertise of agencies like Azoonis ensures you maintain high standards through continuous performance assessments and inspections. Embrace these secrets to unlock the full potential of your supply network, fostering growth, innovation, and sustainability in your business.